-

Product Classification

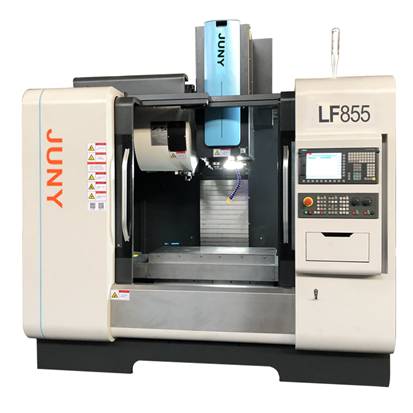

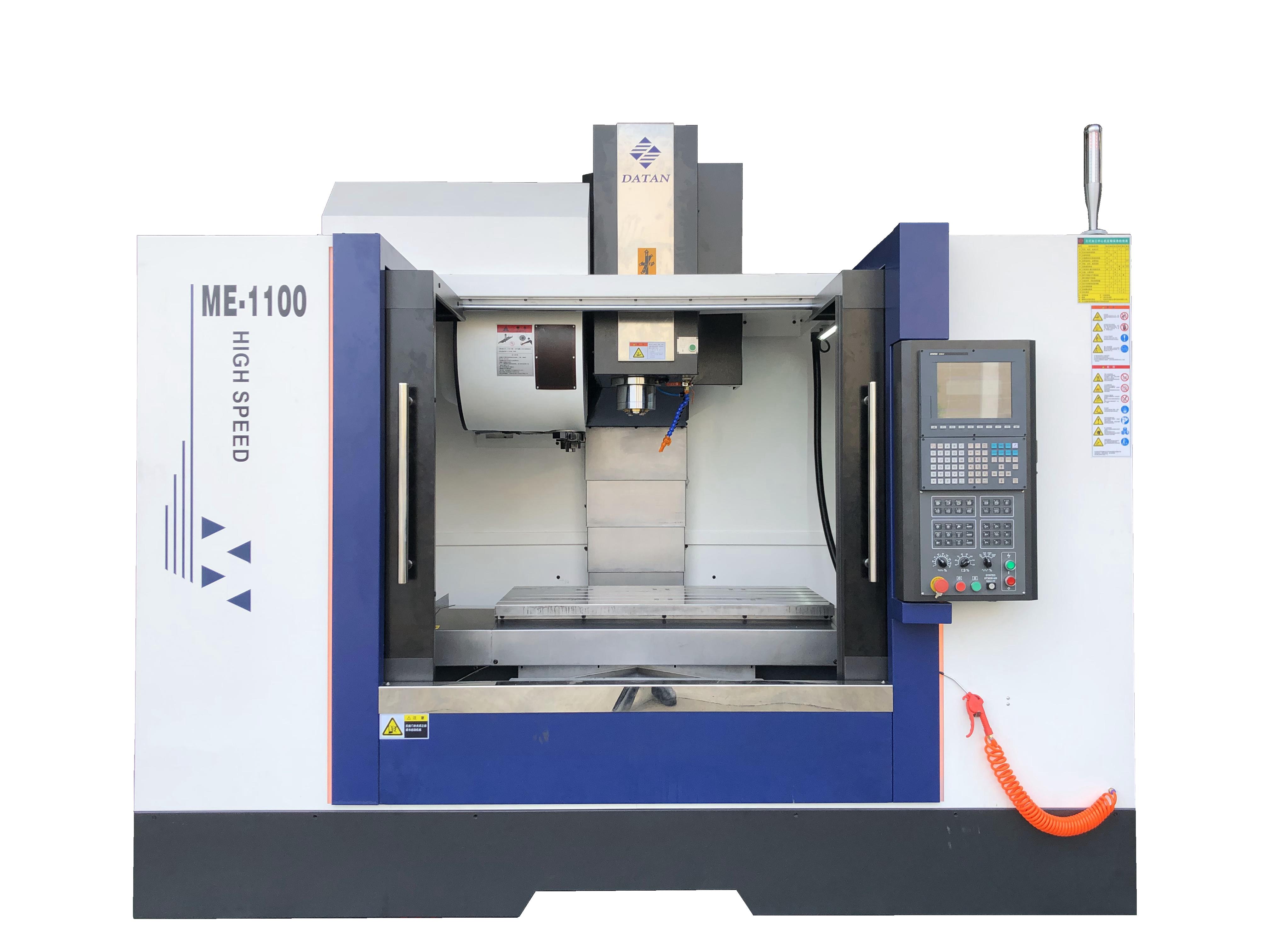

- MILLING

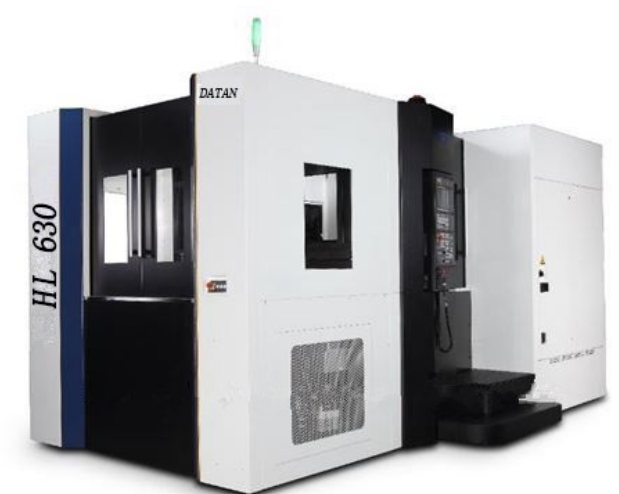

- GANTRY

- CNC LATHE

-

Optional Configuration

-

FK15 Series NC Dividing Head

FK15 Series NC Dividing Head

-

NC Indexing Head

NC Indexing Head

-

Complete Spindle

Complete Spindle

-

Spindle Oil Cooler

Spindle Oil Cooler

-

Electric Spindle

Electric Spindle

-

Spindle Reduction Gear Box

Spindle Reduction Gear Box

-

Gas Cylinder

Gas Cylinder

-

Side Milling Head

Side Milling Head

-

Coolant Trough Spindle

Coolant Trough Spindle

-

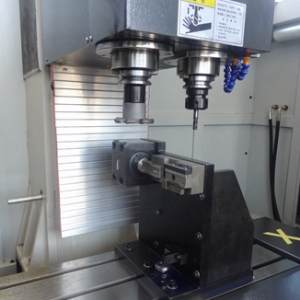

Multiple Spindle

Multiple Spindle

-

Grating Ruler

Grating Ruler

-

Tool Auto-checking Instrument

Tool Auto-checking Instrument

-

Oil Water Separator

Oil Water Separator

-

Automatic AC Voltage Regulator

Automatic AC Voltage Regulator

-

Cabinet Air-Conditioner

Cabinet Air-Conditioner

-

Column Heightening

Column Heightening

-

ER Spring Collect Chuck Systen

ER Spring Collect Chuck Systen

-

cnc milling machine parts-ER Spring Colllets

cnc milling machine parts-ER Spring Colllets

-

BT-MLC Milling Chuck

BT-MLC Milling Chuck

-

Power Milling

Power Milling

-

BT-FMA Face Mill Holder

BT-FMA Face Mill Holder

-

HME Rotary Edge Finder

HME Rotary Edge Finder

-

HME Rotary Edge Finder

HME Rotary Edge Finder

-

SLA Side Lock End Mill Holder

SLA Side Lock End Mill Holder

-

SD Fast Bit Discard

SD Fast Bit Discard

-

EMRW Round Dowel End Mill

EMRW Round Dowel End Mill

-

EMRW Round Dowel End Mill

EMRW Round Dowel End Mill

-

TRS Round Dowel Face Mill

TRS Round Dowel Face Mill

-

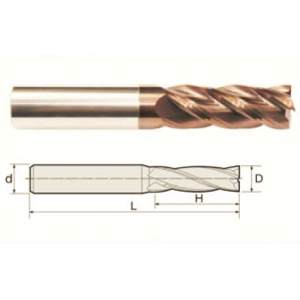

4 Flutes Square End Mills

4 Flutes Square End Mills

-

2 Flutes Square End Mills

2 Flutes Square End Mills

-

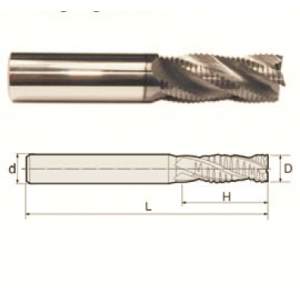

4 Flutes Roughing End Mills

4 Flutes Roughing End Mills

-

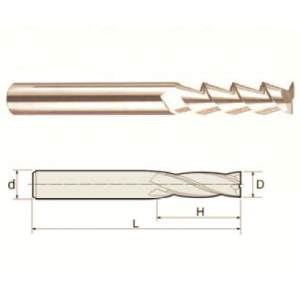

For Aluminum Alloy Processing 2 Flutes Square End Mills

For Aluminum Alloy Processing 2 Flutes Square End Mills

-

H-BIT Double-edged Sword Coarse Sugar Kong

H-BIT Double-edged Sword Coarse Sugar Kong

-

NBJ16 Smail Diameter BORING BAR / HBOR

NBJ16 Smail Diameter BORING BAR / HBOR

-

-

Case

-

Video

-

Service

-

About Us